COTTON:

Cotton is a natural cellulosic fibre obtained from bushy perennial cotton plants. The cotton plant belongs to the species Gossipium. The cotton plant grows and produces a number of pods (bolls) and on ripening, the cotton pods open which contain lot of seeds to which the cotton fibres are attached. This is called the Seed Cotton. The cotton fibres are separated from the seeds by the Ginning process. This is called the Lint Cotton. This Lint Cotton commonly referred as Cotton is sent to Spinning Mills to spin Cotton Yarn.

Fibre Length, Strength, Fineness (Micronaire value), Maturity, Colour and Uniformity are the important requirements for Fibre selection. Fibre Length, Fibre Strength, Microniare value and the type of yarn decide the Count range.

Cotton is a very versatile fibre and is used in many textile and non-textile applications. China, India, USA, Brazil, Pakistan, Greece, Turkey & Uzbekistan are important cotton producing countries.

Since Cotton cultivation requires a huge amount of Pesticides, Genetically Modified (GM) Cotton was developed to reduce the dependency of pesticides. Organic Cotton is produced without the use of insecticides & pesticides.

| Merits | Demerits |

| Strong | Wrinkles easily |

| Absorbent | Shrinks unless treated |

| Comfortable | Easily attacked by Mildew |

| Versatile | Long drying time |

| Non-allergenic | Poor crease resistant |

| Easy to wash | Flammable |

| |

|

JUTE :

Jute is natural cellulosic fibre belonging to bast fibres group. Jutes belong to the family Tiliaceae. The two species are Corchorus capsularis and Corchorus olitorius. The strand of Jute fibres lie just beneath the bark of the Jute Plant. The plant is cut and the Jute fibres are removed from the plant by the retting process. Then the fibres are separated from one another by drying, softening & scotching. The colour varies from yellow to brown. The fibre are coarse and the length ranges from 150 mm to 350 mm. India & Bangladesh are the major Jute producing countries. Jute is the second most important natural fibre nest to cotton and has a variety of uses. Jute fabrics are Hessian cloth and the Jute bags are called Gunny bags. These are very much useful in packing & transporting. Jute is 100% bio-degradable & eco-friendly. It is useful in industrial fabrics, nets, packaging, agriculture, floor covering, ropes, twines, geo-textiles & technical textiles. |

|

WOOL:

Wool, common name applied to the soft, curly fibres obtained chiefly from the fleece of domesticated sheep, and used extensively in textile manufacturing. The fleece of sheep raised for wool is generally shorn once yearly, in the spring or early summer. In regions where the climate is warm throughout the year, shearing may occur twice annually. The fleece is cut close to the skin, usually with mechanical shears, and removed in one piece.

The value of wool on the market depends primarily on fineness and length of fibre. Strength, elasticity, amount of crimp, and uniformity are also considered. Two different systems are followed in wool processing, the woolen system and the worsted system. In the woolen system, the fibres are carded and then spun. In the worsted system, the fibres proceed to a combing process, which separates the long from the short fibres. Before the wool can be used for commercial purposes it must be scoured or cleaned. Scouring & cleaning may be done using warm water, detergent, alkali & carbonization.

Wool is used in clothing, shirting, suiting, woolen sweaters, blankets, upholsteries, felt, horse rug, carpets, insulation.

|

SILK:

SILK:

Silk is a natural protein fibre used in producing textiles. Silk fibres are produced as a cocoon covering by the silkworm. Although cocoon coverings of fibre are made by a large number of insects, only those of the mulberry silk moth, Bombyx mori, and a few other moths closely akin to it, are used by the silk industry.

The cocoons are first heated in boiling water to dissolve the gummy substance that holds the cocoon filament in place. After this heating, the filaments from four to eight cocoons are joined and twisted and are then combined with a number of other similarly twisted filaments to make a thread that is wound on a reel to give filament silk. The damaged outer portion & inner portion of the cocoons after brushing give staple silk which is spun to produce spun silk.

Silk fibres have a triangular cross section with rounded corners. This reflects light at many different angles, giving silk a natural shine.. Silk is used for clothing such as shirts, blouses, formal dresses, high fashion clothes, negligees, pyjamas, robes, skirt suits, sun dresses, underwear, furnishing applications, upholstery, wall coverings, bedding etc.

| Merits | Demerits |

| Lustre & soft | Perspiration & sunlight weakens |

| Strong | Sensitive to alkali & acids |

| Absorbent | Insects attack silk easily |

| Warm & suitable for winter | Yellowing with aging |

| Highly drapable | Leaves water spots |

POLYESTER:

POLYESTER:

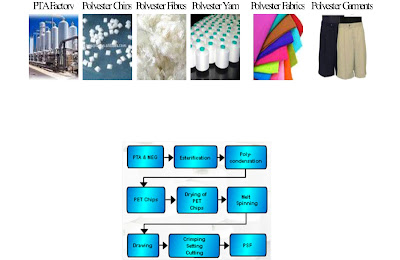

Polyester is a synthetic fibre produced from the polymer Poly Ethylene Terephthalate (PET). PET is produced by reacting Purified Terephthalic Acid (PTA) or Dimethly Terephthalate (DMT) with Mono Ethylene Glycol (MEG). All these raw-materials are from Petroleum products. From the PET polymer Polyester Fibres are produced in various forms namely Staple Fibres (PSF) and Filament forms Partially Oriented Yarn (POY), Draw Textured Yarn (DTY), Fully Drawn Yarn (FDY).

PSF are produced in cut lengths of 38, 44 & 51 mm and in deniers of 1.0, 1.2, 1.4, 1.5, 2.0, 2.25 and 3.0. POY have deniers of 51 to 245 with number of filaments between 14-34. Crimping is done PSF which facilitates production of spun yarns.

PSF are sold in various strengths namely Low-pill fibres, Medium Tenacity, High Tenacity & Super High Tenacity. Various lustre level fibres are available like Bright, Semi dull, Dull & Extra dull.

Polyester woven fabrics are used in apparel and home furnishings such as bed sheets, beds, curtains and draperies. Industrial polyesters are used in tyre reinforcements, ropes, fabrics for conveyor belts, safety belts, coated fabrics and plastic reinforcements with high . Polyester fibre-fills are also used to stuff pillows, beds and cushion padding.

Polyester fabrics have a "less natural" feel when compared to natural fibres like cotton in textile uses. Polyester fibres are spun together with other natural fibres to produce a cloth having the merits of both synthetic & natural fibres.

| Merits | Demerits |

| Strong | Collects static electricity |

| Wrinkle & abrasion resistant | Sensitive to heat |

| Shrink resistant | Pilling |

| High dimensional stability | Low moisture absorption |

| Mildew resistant | Affinity for oily stains |

| Easy care | Melts in fire |

VISCOSE RAYON:

There are many types of Rayon namely, Nitrocellulose, Acetate, Cuprammonium, Viscose etc., Here we consider Viscose rayon only. Viscose Rayon is a regenerated cellulosic fibre. It is made from cellulose extracted from wood pulp produced from trees. The wood pulp obtained from trees is bleached and then sent to Rayon factories in the form of sheets and boards which contains about 87 to 98% cellulose.

The Viscose fibres are produced both in filament form & staple form. The fibres are produced in cut lengths of 28, 32, 38, 44, 51 & 60 mm for cotton spinning system. The deniers are generally 1.2, 1.5, 2.0, 3.0 & 4.0 .

Rayon is a very versatile fibre and has the same comfort properties as natural fibres. It can imitate the feel and texture of silk, wool, cotton and linen. Rayon is easily bio-degradable. Rayon is used in making apparel (e.g. blouses, dresses, jackets, lingerie, linings, scarves, suits, ties, hats, socks), furnishings (e.g. bedspreads, blankets, window treatments, upholstery, slipcovers), industrial uses (e.g. medical surgery products, non-woven products, tire cord), and other uses (e.g. yarn, feminine hygiene products, diapers)

High Wet Modulus rayon (HWM) is a modified version of viscose that has a greater strength when wet and can be mercerized like cotton. HWM rayons are also known as “POLYNOSIC“.and has a trade name MODAL. High Tenacity rayon is another modified version of viscose that has almost twice the strength of HWM. This type of rayon is typically used for industrial purposes such as tyre cords.

| Merits | Demerits |

| High absorbency | Easily felts in moist heat & friction |

| Provides warmth | Stretches during wear |

| Wrinkle resistant | Easily attacked by moths |

| Elastic | Allergic to some people |

| Can be easily dyed | Builds up static electricity |